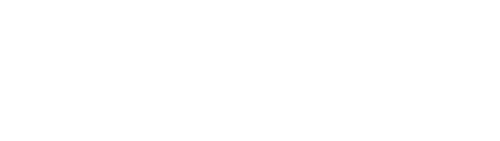

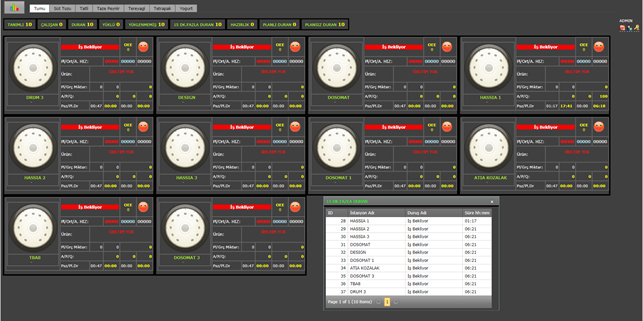

Production quantities, breakdown durations, production orders, manually breakdown inputs, waste and scrap data will be collected and the following analysis will be possible and error through the counter and breakdown signals to be received from the machines.

TREX DCAS EFFICIENY AND PRODUCTION MONITORING SYSTEMS

Why trex DCAS?

- We are a Software and Electronical R&D Center with Aproval of the Ministry.

- Doing our best to meet the customer specific requirements.

- We have a web based HelpDesk support portal avaliable specifically for our customers in order to check post-sale support.

- We do not waste your sources. If you wish we can work on Cloud technologies. trex

- DCAS is the only application that can run with Cloud technologies.

- World’s giant Coca Cola is utilizing from our products in order to online monitor their production and collect data from equipments over 5000 in more than 100 production plant from currently 38 countries and using 4 Vistual Cloud Server in order to do all of it.

- Our technology is expandable and customizable in an advanced level based on customer requirements when compared to our competitors.

- We have mastered in IOT(internet of the objects) and focued on Industy 4.0 and investing in R&D in this direction.

- All software, HMI(Operator’s Panels), 10 cards that we’re currently using in our projects have been designed and produced in our plants by utilizing TÜBİTAK R&D supports.

- What we do is PRODUCE&SELL instead of BUY&SELL.

- We have TSE ISO 27001, TSE ISO 9001, TSE ISO 15504 SPICE and CE Certificates.

- We offer Competetive and Measurable budgets.

- We provide Work station, Personnel, Work order based online monitoring.

- Customers can automatically make machine based production planning through the online data.

- Customers can take work station, machine and personnel based efficiency and capacity reportings in detail from the system.

- All the data can be historically reported in an expandable and limitless way.

- Complete monitoring is possible including order, product, work station, work center, machine and personnel.

- All the items affecting the cost can be online monitored.

ANDON MANAGEMENT

Andon Board is a visual control device that is generally right above production lines and display current status of production system and alerts about upcoming problems.

It’s a software-supported electronical system developed for the business to see the costs and minimize them. At first Andons were used as the lights, columns with lights and then turned out to be lamp groups and boards. With the technology they are spread as digital boards with led. With the development in PC PLC technology, these boards turned into a visual management and process control devices. As using LCD/Plasma TV all the information, charts and alerts on it can be shifted online in Trex DCAS Andon boards. In one TV, more than one lines can be displayed.

Trex DCAS Andon Boards can be also used for notifications, alerts and warnings. (Enjoy your Lunch, Welcome, Job Safety Warnings, Birthday Celebrations etc.)

- Online monitoring of machine and line production speeds

- Breakdowns reasons of the machines that are in breakdown

- Performance, quality, OEE and efficiency values

- Capacity usage and compactness ratios

- Any information from the database can be displayed in trex DCAS Andon boards over TCP/IP protocole.

- Possibility to input quality data to data collection terminals in the workshop

- Creating reporting substructure, recording statistical process control(SPC) data

- Monitoring input, process and finished product controls and analysis of the results

- Providing supplier error notification and customer complaint management

- Quality KPI management, analysis and reportings

- Administrative acceptance, technical acceptance, first approval and frequencies control inputs, Supplier error notification form, Interior/Exterior Regulative preventive activity tracking form, Regulative activity request form (8D), 100% Control tracking list, Document tracking list A module including sample measurement request bill form, process approvals, suggestion tracking input

- Maintenance and breakdown work orders creation

- Recording and reporting actual maintenance services

- Creation of maintenance plans

- Creation of maintenance service requests

- Identification of breakdown intervention durations

- Breakdown, MTTR and MTBF analysis Maintenance KPI management and reportings

- Periodical maintenance identification and tracking based on time and condition over the system

- Preventive and Predictive maintenance identification and tracking

- Maintenance labour and cost analysis

- Planned-Actual Maintenance analysis based on prices

We have web based reporting and online monitoring tools within trex DCAS system. Through these tools all the loss can be online monitored on machine, equipment, line, personnel and work order level. Thanks to the mobile technologies the production and all the processes can be monitored even outside of the workshop. WEB and IOS (iPHONE) and ANDROID applications are avaliable.

DCAS workshop data collection system can run integrated with several ERP systems. Please see these ERP systems and the details of integration work in the following.